Sales Order Entry

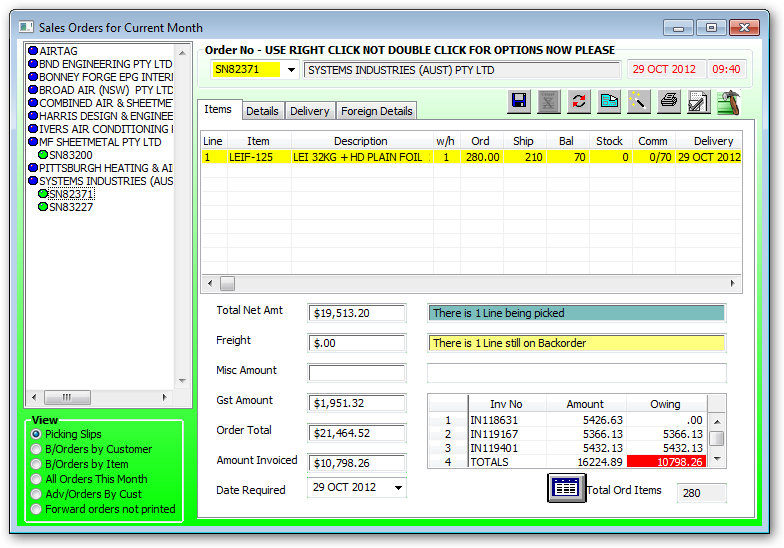

The sales orders displayed depends on the VIEW selected. The display when first entering the sales order function are all the sales orders with a picking slip, then this view may be changed by selecting the required view from the view option below.

The colours displayed in the order list is dependent on the view selected and is as follows:

Picking Slip view:

The icon colours of the company names are as follows:

Dark Blue: Not ready for release as there is no stock

Red: Company on stop credit

The icon colours of the sales orders are as follows:

Green:

B/Orders by Customer View:

The icon colours of the company names are as follows:

Dark Blue: Not ready for release as there is no stock

Red: Company on stop credit

The icon colours of the sales orders are as follows:

Green: Ready for release.

Light Blue: Ready for release but delivery date is not due.

Yellow: No stock available for release.

B/Orders by Item View:

All Orders this Month View:

Adv/Orders By Cust View:

•Picking Slips

•B/Order by Customer

•B/Order by Item

•All Orders This Month

•Adv/Orders by Cust

o**ADVANCED ORDERS **

o

oA new procedure within the RAISE NEW SALES ORDER function called "ADVANCED ORDERS", has been developed by Chris, to enable processing of present day Sales Orders which have a FUTURE delivery date, or dates...

o

o. for eg: A PROJECT PRICE has been agreed with customer A for 125mm Spigots. Customer A has told us that he will start the project in say 2 months, and that it will last for a further 3 months and during those 3 months he will need to draw down on a total of 2000 of 125mm Spigots.

o

oNow, whereas a NORMAL SALE procedure follows the sequence of..: the order is received, the Sales Order is entered, the Picking Slip is generated, the goods ARE in stock,the goods are picked, delivery docket is created, and the goods are delivered and the invoice is sent....but....if, all or part of the order IS NOT IN STOCK a BACK ORDER is created, meaning that when the stock levels are replenished, the back order is supplied IN TOTAL..this does not give us the capability to forward deliver, at a set price, PARTS of a total order over a future period of time.

o

oADVANCED ORDERS, now gives the facility to ..receive an order, create a sales order for the TOTAL number of goods required at the price agreed, enter the end date (estimated) of the Project, and then RELEASE parts of that whole order ( always quoting the original SN number) as and when the customer so directs us, until the total is reached.

o

oNOTE..therefore, that a SEPARATE Sales Order must be raised for EACH "Advanced Order" type transaction....Do NOT MIX normal product sales with advanced order type sales

o

oAs you enter a Sales Order in the usual way..the Item code will be entered with the TOTAL of goods ( of this type)required for the Project. A delivery date being the the END DAY of the Project (approx) will be entered in "delivery date" box.

o

oSHIP QUANTITY will be entered with a zero (0) or, a figure less than the TOTAL..this will cause a popup to appear requiring the person creating the sales order to designate the goods either "B" for Back order..meaning, when the goods are in stock then ALL of the back order quantity will be released...OR..as "A" for Advanced Order, meaning that bits of the total order can be released and delivered at various FUTURE Dates.

o

oAn "ADVANCED ORDERS" summary will be produced as a report at the bottom of the daily STOCK REORDER REPORT..though the quantities of Advanced Orders WILL NOT be included ( as a stock commitment) in the Daily Stock Reorder Report UNTIL the end month of the project is reached, the forward off take schedule given by the customer at the start of the transaction should be used by the Purchasing Officer as an important ingredient of the quantity of stock repurchasing needed to sustain stock levels at required levels when each reorder report is produced .

o

•Forward Orders Not Printed

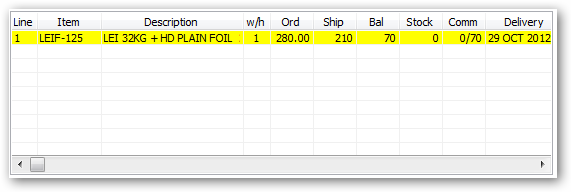

Left Click on the invoice table then right click for:

➢View Details

➢Purchase Orders

➢Work Orders

➢Committed Stock

➢National Stock

➢Description

Total Net Amt:

Freight:

Misc Amount:

GST Amount:

Order Total:

Amount Invoiced:

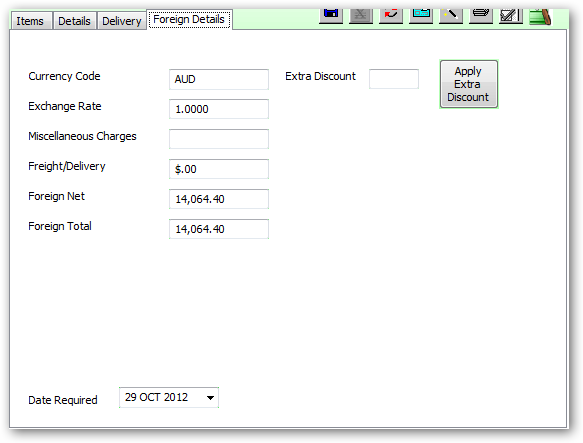

Date Required:

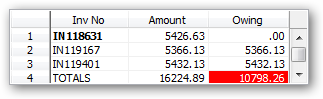

Left Click on the invoice table then right click for:

➢View Invoice

➢Print Invoice

➢Print Delivery

➢Print Order Confirmation

➢Print Pro Forma Invoice

This view displays all sales orders which have a picking slip record. Those pricking slips which have not been printed will be displayed in GREY in colour.

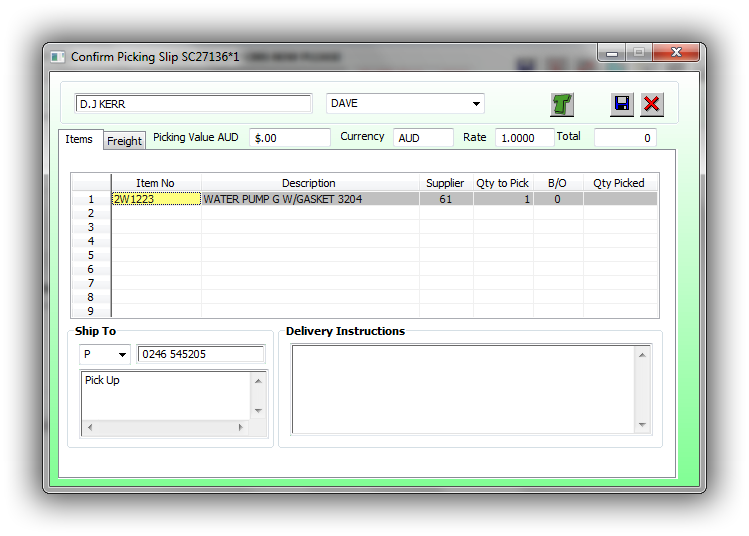

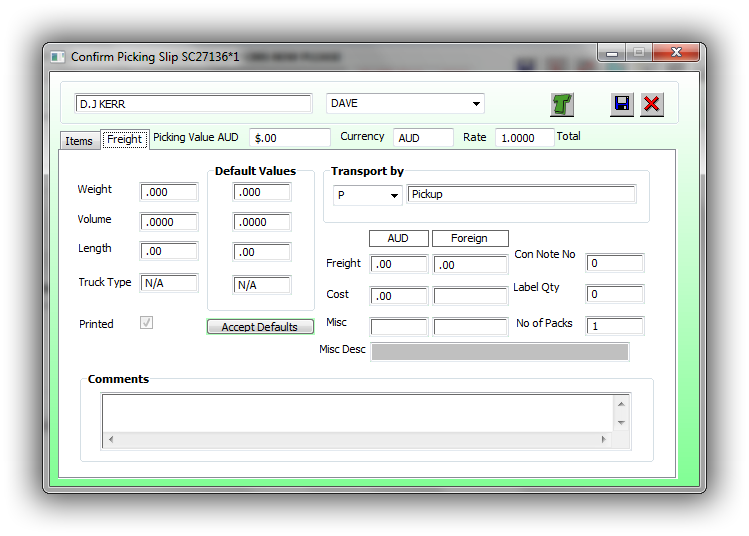

Double click on the picking slip details to start the confirmation.

Enter the qty picked. Press the enter key to use the default qty

Press the transfer button to complete the sales order confirmation.