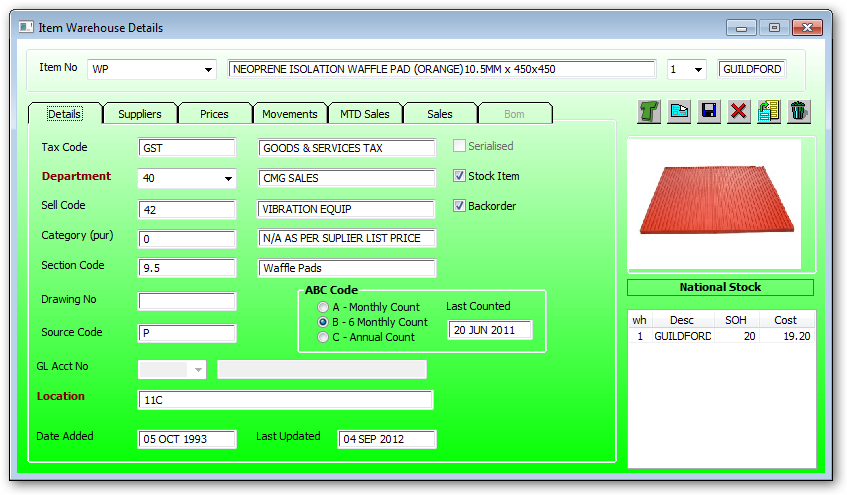

The warehouse details file contains all the inventory details for this item in this warehouse. Details such as warehouse location, Supplier prices movements etc are found here.

Enter an existing item number or enter any part of the item description to invoke an inventory search.

Description:

The description is as per inventory file.

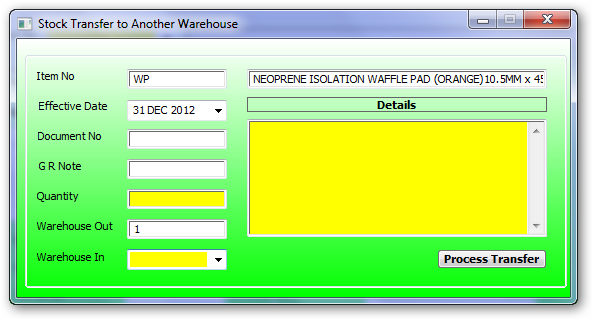

Transfer Stock To Another Warehouse:

Click on the tab with the green t on the right side of the screen. (transfer stock to another warehouse)

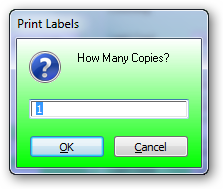

Click on the process transfer box. You will then get a message that the transfer is complete. Click on ok and this will take you back to the item warehouse details screen. If you have more stock to transfers click on the green t button and continue on. When you have finished all the transfers click on save and exit.

Use the warehouse recall button to display previously displayed warehouse records while not existing this warehouse session. If the session has been canceled the this recall list will be reset.

Tax Code:

Sell Code:

Category (Pur)

Section Code

Drawing No:

Source Code:

Serialised:

All the above codes are for DISPLAY only and are determined by the inventory master file NOT the warehouse details file.

Enter the general ledger department. This is the department of the owner of this item in this warehouse. There can only be one owner of any product within a warehouse.

Press the dropdown to display available options.

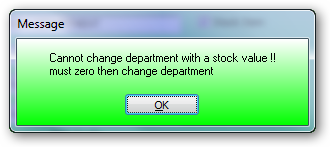

NOTE:

Do not change the department of existing warehouse details records that have a standard cost and there are stock qtys. This is because a change of ownership has an impact on the general ledger stock valuation. If a change of department is required then change the qty on hand to zero using the manual stock take function, change the department then reinstate the qty on hand using the manual stock take function.

Enter the location of this item within this warehouse. This location is printed on a number of reports such as picking slips etc.

This location is also used cycle counting by warehouse location.

Tick this box if this is a stocked item. If not stocked this item will not be included in the reorder report.

Tick this box to allow back order in the order entry module. Do not tick this box for items not to be ordered in

If the qty on hand is a blank i.e there have never been any transactions in this warehouse for this item, then NO NATIONAL STOCK DETAILS WILL BE DISPLAYED.

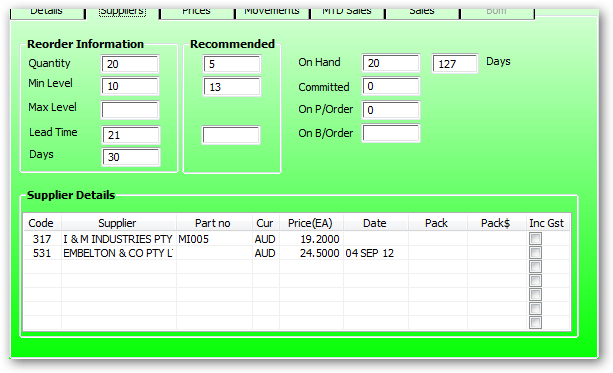

Quantity:

Enter the number of items to be purchased. Used as a default qty during in the purchase order modiule.

If a maximum level has been entered then the larger of REORDER QTY and MAX LEVEL - STOCK ON HAND will be used in the purchase order module.

Min Level:

The reorder level is used to override the recommended re order level calculated by the inventory system. If the reorder level is greater thant the calculated reorder level then this greater amount will bed to include this item on the reorder report.

If the reorder level is left blank then this item will not be included on the re order report.

Max Level:

Enter the maximum number of items to be in stock after purchasing the recommended qty. The qty used during in the purchase order module is the difference between the MAX LEVEL and STOCK ON HAND.

If a Reorder qty has been entered then the larger of REORDER QTY and MAX LEVEL - STOCK ON HAND will be used in the purchase order module.

Enter the days taken from order date and and deliver date in days. Enter Zero to force the ship quantity to be equal to the order quantity even though there may not be any stock available.

Number of days between purchase orders.

This is to minimise delivery costs for each order of the one supplier.

These days will be added onto the lead time days for reordering purposes.

Non stocked items are not included in this calculation.

Recommended:

Quantity:

Min Level:

Lead Time:

On Hand:

Days:

Committed:

On PO/Order:

On BO/Order:

Code:

Enter the creditor code or enter any part of the creditor company to invoke a creditor company search.

If there is an existing creditor then double clicking the creditor code will display the creditors details inquiry window.

Right click to display supplier costing inquiry for this item and this creditor.

Note:

The supplier costing is an inquiry window and no changes may be entered.

Part No:

Enter the supplier part number or code. This code is printed as part of the description (in brackets) on the purchase order. This is to aid the supplier in delivering the correct item on the purchase order.

Currency:

Warehouse Supplier Currency Code.

Price:

Enter the default price used iby the purchase order module. If the currency is the same as the currency in the creditors master file. I.e If this supplier is a foreign supplier then the supplier price should also be in this foreign currency.

Date:

Enter the date at which the last price was updated.

Pack:

Warehouse Supplier Pack Uofm.

GST:

Check the GST if the supplier price includes GST.

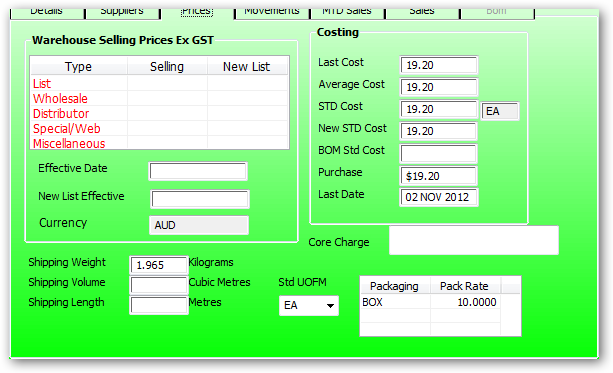

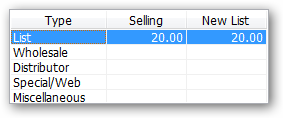

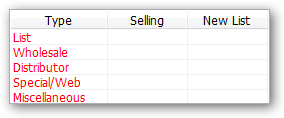

Warehouse Selling Prices Ex GST:

If the prices below are displayed in black then the prices are determined by prices in the inventory master file (national stock) and are for display only. Any changes are made via the inventory master file.

If the price below are displayed in RED prices are maintained here in the warehouse details file. Warehouse pricing is controled by the check box in the warehouse master file

If the warehouse pricing has been enabled in the warehouse master file then instead of national pricing as determined by the price in the item master file, the selling prices are set by the prices in the warehouse details file.

This allows fixed international pricing for each warehouse in the currency determined by the warehouse master file.

Warehouse Details effective date.

This is for display only and are defined in the inventory master file.

Shipping Weight

Shipping Volume

Shipping Length

UOFM

Packaging:

This is for display only and the packaging is defined in the inventory master file.

Pack Rate:

Warehouse Packaging Rate:

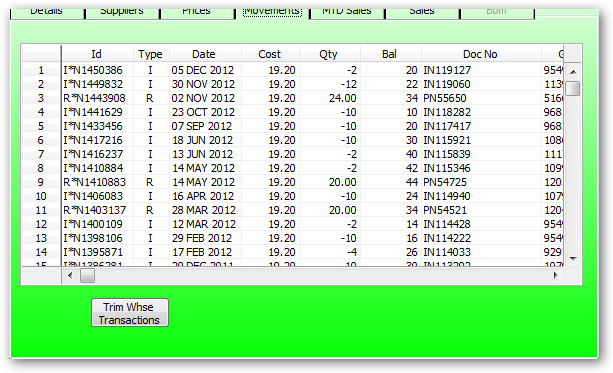

ID:

Double click on Id to display the transaction details posted to the general ledger.

Type:

The type indicates the kind of source document. (I)invoice (R)eceipt (W) work order.

Doc No:

Double click on Document number to display the source document. The document types include invoice, purchase order and work orders.

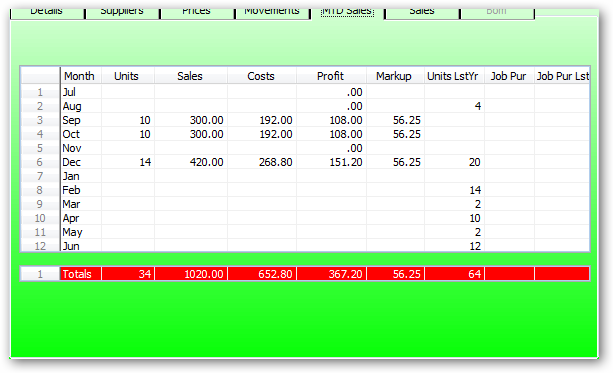

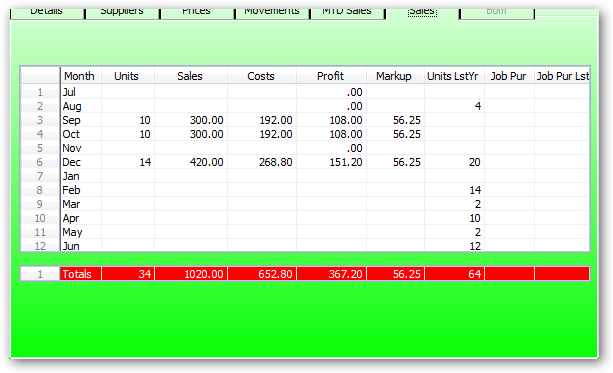

Press this Trim Whse Transactions button to trim the number of transaction of this item to say 500 transactions.

If you are not authorised to perform this function please consult your system administrator to perform this function OR ask the administrator to give access to "user Access in Module" from the System Functions menu.